Why Dissolved Molecular Oxygen Outperforms Nano Bubble & Micro Bubble Technology in Aquaculture

In aquaculture, maintaining stable dissolved oxygen (DO) levels is critical — directly influencing animal health, feed conversion efficiency, and sustainable growth performance. While traditional aeration systems are still commonly used, many farms have begun upgrading to microbubble and nanobubble technologies in hopes of improving results.

However, despite some advantages, these technologies come with inherent limitations. This article dives deep into the current oxygenation methods and explains why RYNAN’s bubble-free molecular oxygen dissolution technology offers a more effective and sustainable solution for modern aquaculture operations.

Limitations of Nano and Micro Bubble Oxygenation Systems

Micro and nano bubble systems work by generating ultra-fine gas bubbles to increase the contact area between air and water, thereby enhancing oxygen diffusion. Some systems even use pure oxygen to boost performance.

Yet fundamentally, these methods cannot overcome three critical limitations:

1. Continuous Oxygen Loss at the Surface

Bubbles, by nature, rise. Whether micro or nano, they eventually reach the surface and burst, releasing oxygen back into the atmosphere. The smaller the bubble, the slower it rises — but oxygen loss remains unavoidable. This means part of the oxygen and energy input is inevitably wasted.

2. Unstable DO Levels

DO concentration fluctuates depending on bubble diffusion rates, which are influenced by uncontrollable environmental factors:

Temperature: Warmer water holds less oxygen.

Salinity: Higher salinity reduces oxygen solubility.

Atmospheric Pressure: Weather changes can affect oxygen retention.

This instability creates a suboptimal, often stressful environment for aquatic animals.

3. Potential Harm to Shrimp at High Bubble Densities

A lesser-known yet serious risk: high concentrations of nano bubbles can harm shrimp.

Mechanism: Excessive micro/nano bubbles may cause localized oxygen oversaturation. When these bubbles burst near shrimp gills, they release reactive oxygen species (ROS), leading to oxidative stress.

Consequences: Oxidative stress can damage gill tissue (causing hyperplasia or fusion of gill filaments), impair respiration, and even damage hemocyanin — the shrimp’s oxygen-transport molecule. This leads to systemic hypoxia, even when measured DO levels appear high.

RYNAN’s Solution: Direct Dissolution of Pure Molecular Oxygen

Instead of creating bubbles, RYNAN’s approach focuses on directly dissolving pure oxygen molecules into water. The key difference is that oxygen becomes fully integrated at a molecular level — not encapsulated in gas bubbles.

RYNAN Oxygen Generrator

How It Works:

Pure Oxygen Generation: RYNAN’s PSA (Pressure Swing Adsorption) technology extracts and concentrates oxygen from ambient air, achieving purity up to 93%.

Molecular Dissolution: The pure oxygen is introduced into a specialized unit that dissolves it entirely into water — with no bubbles formed.

Sustained Retention: Since the oxygen is molecularly bound within the water, it remains available until consumed by aquatic organisms — with zero atmospheric loss.

Key Advantages of RYNAN’s Molecular Oxygen Technology

✅ Maximum Efficiency & Long-Term Stability

Oxygen is retained in water, ensuring DO levels remain stable around the target range — regardless of time, temperature, or salinity.

✅ Up to 70% Energy Savings

Energy is focused solely on generating and dissolving oxygen, eliminating inefficiencies from bubble formation and gas loss. This significantly reduces operating costs.

✅ Safe for Shrimp

Without micro or nano bubbles, there’s no risk of oxidative stress or gill damage — resulting in a healthier, more stable growing environment.

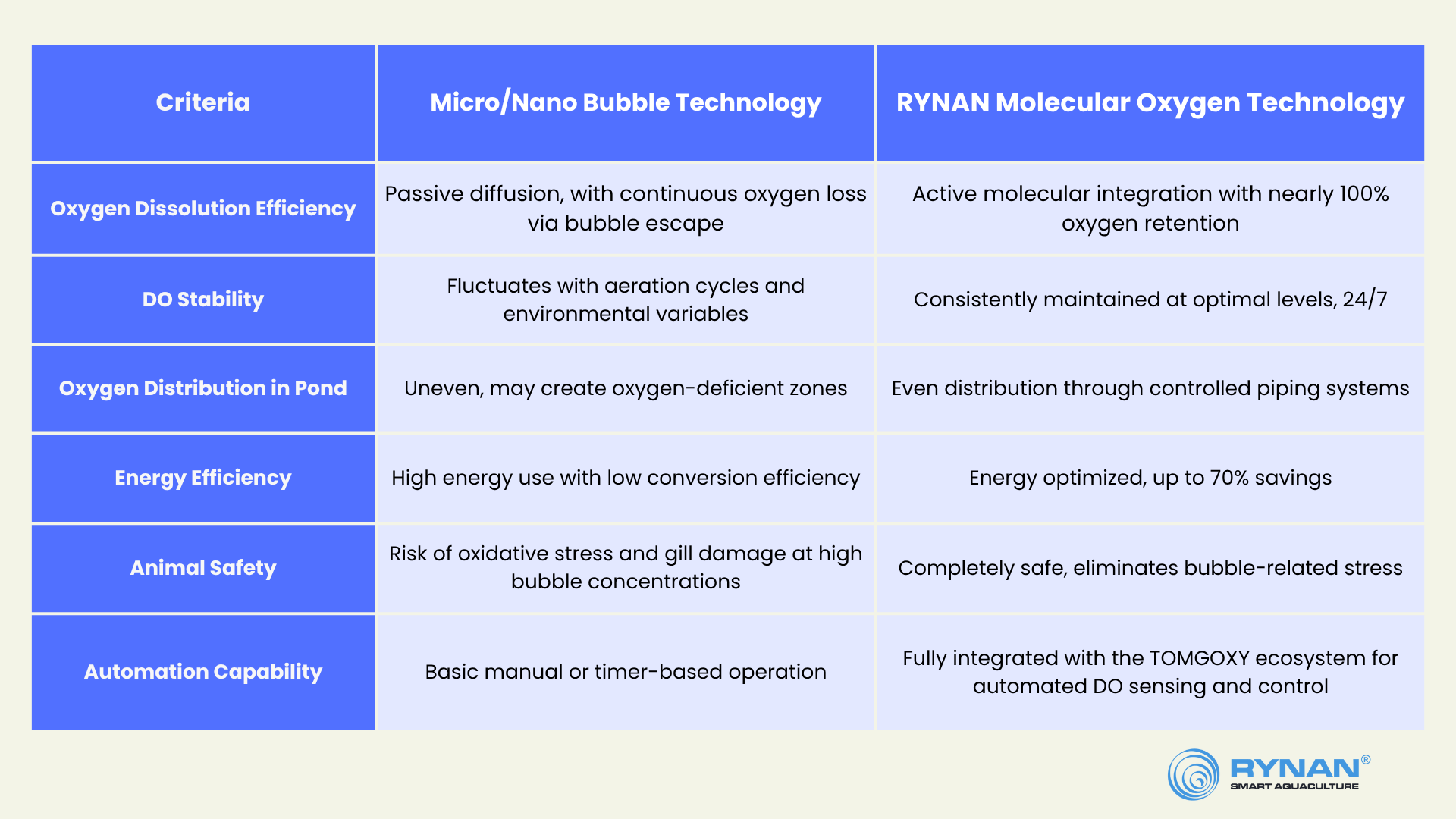

Visual Comparison Table: Molecular Oxygen vs. Bubble Technology

RYNAN Molecular Oxygen TechnOLOFY vs. Micro/Nano Bubble Technologies

Real-World Results: Performance Gains from Technology Adoption

Farms adopting RYNAN’s complete oxygen management solution — including oxygen generators, water distribution systems, and TOMGOXY application — have reported outstanding improvements:

Ideal DO Range Maintained: Automated systems maintain DO levels at 7–10 mg/L — ideal for shrimp health and growth.

Improved FCR and Survival Rates: With stable DO and reduced stress, shrimp eat more efficiently, grow stronger, and show higher survival rates.

Faster, More Uniform Growth: Healthier conditions accelerate growth, shorten crop cycles, and increase yield per unit area.

Time to Upgrade Your Oxygen Management System?

Tason Farm – Our Partner in Thailand

Vietnam’s shrimp industry is entering the era of precision aquaculture — where every input must be tightly controlled. Relying on outdated aeration systems means accepting risk and missing out on growth opportunities.

Investing in molecular oxygen technology isn’t just about buying a machine. It’s about adopting an intelligent, automated ecosystem that helps you:

Precisely control water quality

Minimize operational and labor costs

Maximize profitability each cycle

If you're ready to end the guesswork and unlock your farm’s full growth potential, it’s time to explore RYNAN’s molecular oxygen solution.